Liquefied Natural Gas Facilities

Liquefied natural gas (LNG) is economical and its global use is growing, but the process has unique risks.

Life safety and asset protection is paramount

Protecting liquefied natural gas (LNG) processing and storage sites and transportation vessels present a unique set of risks.

Mitigating these risks requires high-performance flame and gas detection and suppression systems, plus a track record of successfully protecting these facilities and their staff. Det-Tronics offers a robust, reliable solution, proven in sites around the world.

LNG hazard detection challenges:

Performance and design requirements vary by facility/zone/area

Flammable and non-flammable (toxic) hazards create the need for multiple detection types and technologies

Environmental factors such as wind and extremely low temperatures increase the complexity of the solution’s design

False alarm sources increase the potential for unnecessary, disruptive risk mitigation activations and process shutdowns

Complete solutions must:

Provide reliable detection under varying environmental factors

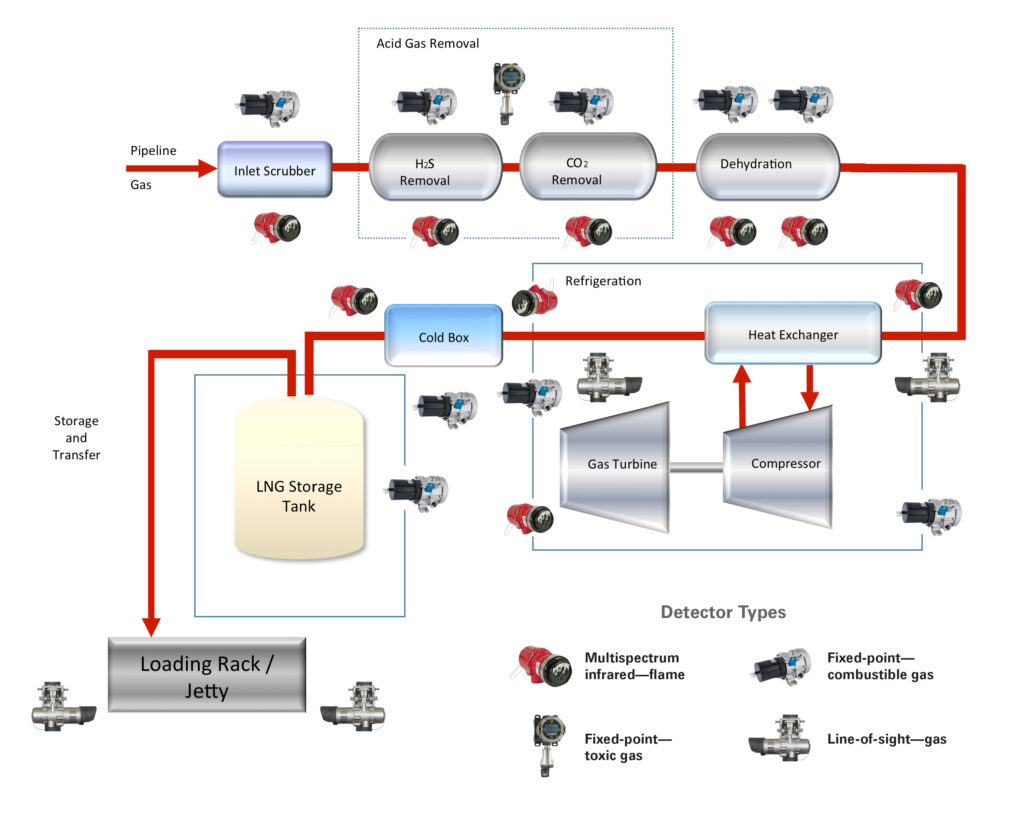

Include detector types and technologies to address needs at different stages of the LNG production process

Provide enhanced immunity to false alarm sources and be unaffected by sources of electromagnetic interference

Integrate detection, notification and suppression functionality

Automatically initiate corrective action, including engaging the emergency shutdown (ESD) system

Place and aim detection equipment for optimum coverage

Validate performance during commissioning

Use a performance-based design that complies with local, national and international codes and standards